Suitable for spun yarn.

Beam diameter (mm) :

800 , 1000, 1250, 1400Working width (mm) :

1400-2800Max. working speed (m/min) :

1000Press form :

Pneumatic parallel pressLength (mm) :

2120+ Working widthWidth (mm) :

1860, 1980, 2130, 2370Height (mm) :

1800, 2000, 2250, 2550

As a professional warping machine manufacturer, H-FANG presents our latest direct warping machine – the 128H – which delivers high productivity and exceptional quality.

This direct warper is equipped with a unique parallel damping pressure system, ensuring flatter warp beam control. Coupled with the roller centering function, it precisely guarantees warping quality.

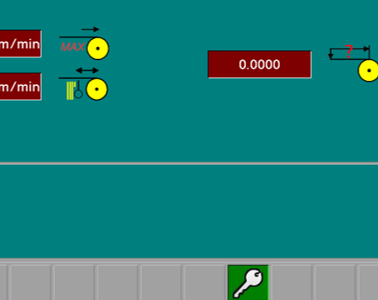

It further supports remote control and data interconnection with ERP and MES systems, intelligently empowering production.

Choose the 128H direct warp machine from H-FANG, a trusted warping machine manufacturer, to let efficiency and precision run through every warping operation.

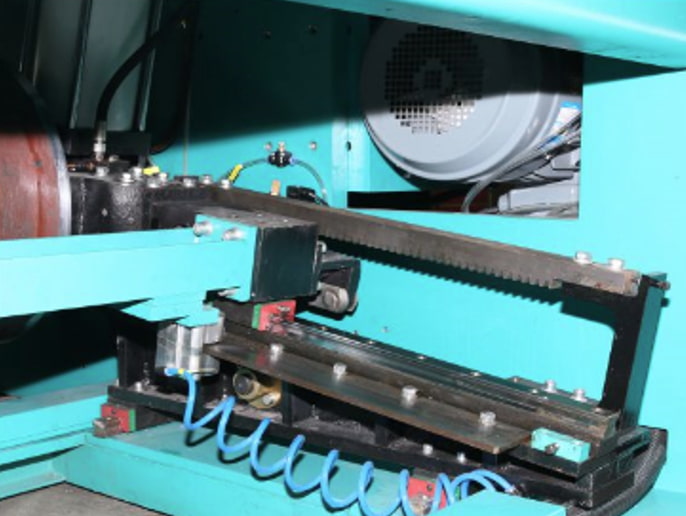

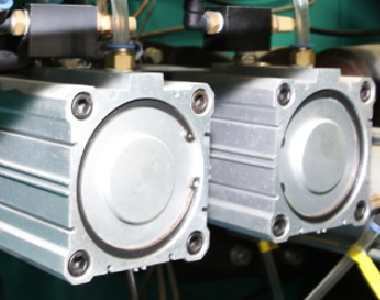

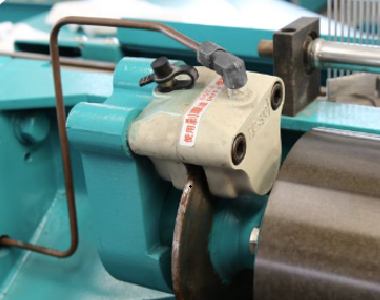

Constant damp device

During high speed running of the beam, press roller will jump front & back if the roundness of the beam is not good. To avoid press roller jump, and guarantee the beam quality and safety, the machine is equipped with two pneumatic damp device. After press roller is pressing on the beam, jumping of press roller can be reduced by increasing damping force.

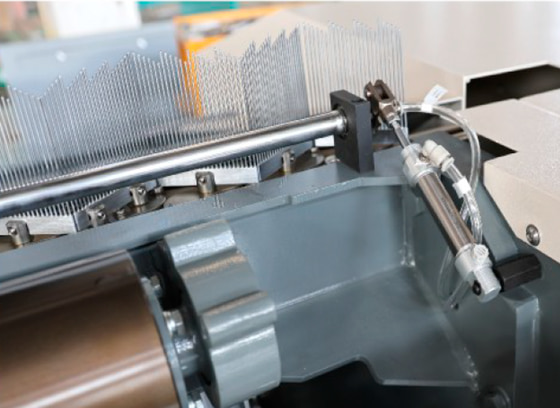

Blow & Tidy Device

Blow

Intermittent blowing to clean the fly from the reed, prevent too much waste from winding into the beam, affect beam quality. Blowing time and the interval time can be set.

Tidy

Tidy the yarn as per set interval time for better yarn arrangement to wind into the beam, prevent the yarn from crossing and yarn breakage when unwinding(in sizing or slasher processes)

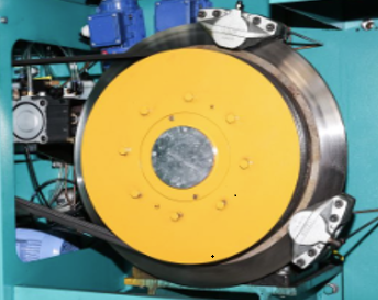

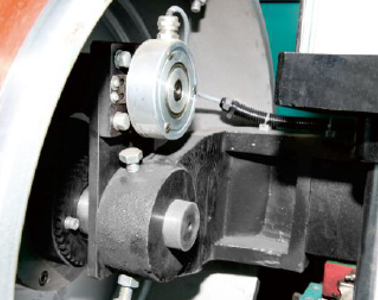

Brake System

Air-liquid Assembly Brake

Faster response, brake distance can be controlled within 3m at machine speed 500m/min, efficiency of breakage re-connect can be increased.

Brake of multiple positions at same time

Corresponding brakes are mounted on main shaft, guide roller, press roller, etc... Brake at same time when machine stops which can reduce the yarn friction in guiding channel.

Fast backward of press roller

When press roller brakes, the roller moves backward immediately getting away the yarn surface. Prevent the roller wearing the yarns due to brake time difference between main shaft and press roller

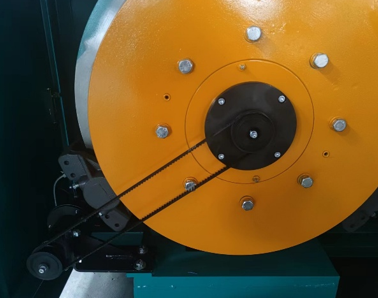

Length Counter

Main length counter

When machine is running, one encoder at one side of the press roller is recording the warping length

Assistant length counter

To avoid counter error due to the press roller and main shaft are out of synchronization, another encoder is mounted on one side of main shaft, when machine stops, the assistant counter records the warping length

Counter coefficient

If affected by other factors, counter coefficient can be set to control the accuracy of warping length

1. How long is the delivery time?

The delivery time varies depending on the model and configuration. Under normal circumstances, the delivery time is 40-60 days after the date receiving down payment.

2. How long is the warranty period?

The seller provide 12 months guarantee after installation or 15 months after delivery, subject to the prior expire.

3. Can the machine be customized?

Yes. We can customize the machine according to your needs?

4. Do you provide installation service?

Yes, we do. We will send engineers to the site for installation, commissioning, and training of staff on operation.

Leave A Message

Scan to Wechat/Whatsapp :