HF928R High Speed Automatic Sectional Warping Machine can warp any staple yarn and filament.

Beam diameter (mm) :

φ800, φ1000, φ1250Working width (mm) :

2300~5400Max. section width (mm) :

770Max. working speed (m/min) :

1000Max. beaming speed (m/min) :

300The 928R sectional warping machine, as H-FANG's high-end high speed sectional warping machine, boasts numerous unique advantages: The large cage reverse winding design enhances warping quality while making operation more convenient; the beaming part adopts hydraulic control, offering superior stability. In addition, practical functions such as the visual yarn break self-stop system are available as options.

For more details about this sectional warping macher, please feel free to contact us for an in-depth understanding.

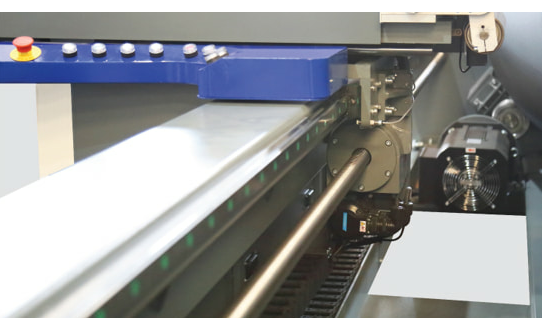

Drum Anti-clockwise Direction Rotation

- Clockwise direction rotation reduces spreading angle for better warping quality.

- Fixed guide roller ensures even yarn alignment, enabling smoother operation and higher efficiency.

- An air jet nozzle mounted ahead of the guide roller enables scheduled reed cleaning.

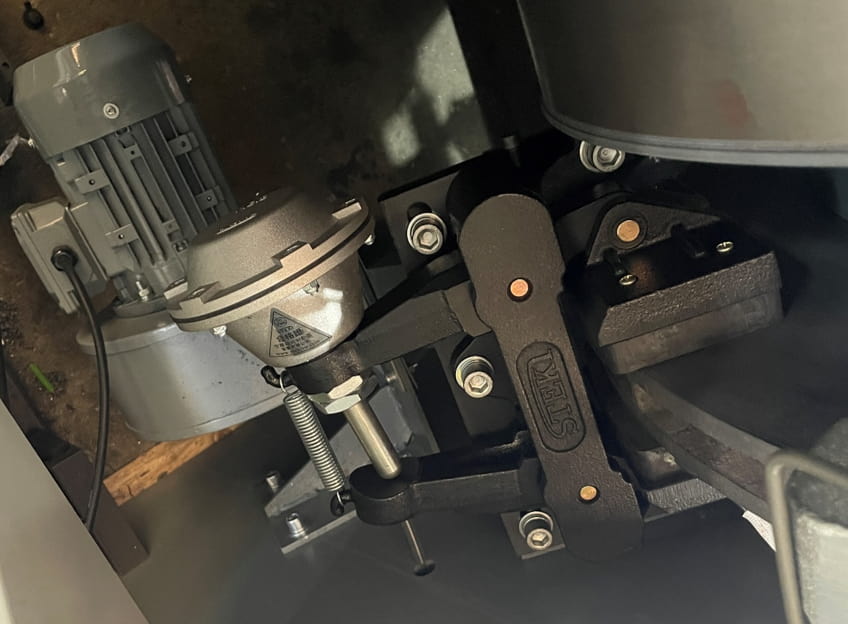

More Stable & Compact Drive Mechanism

- Automatic thickness detection for the first section.

- Dual linear guiderail, opposing linear guide configuration significantly enhances stability and reduces vibration.

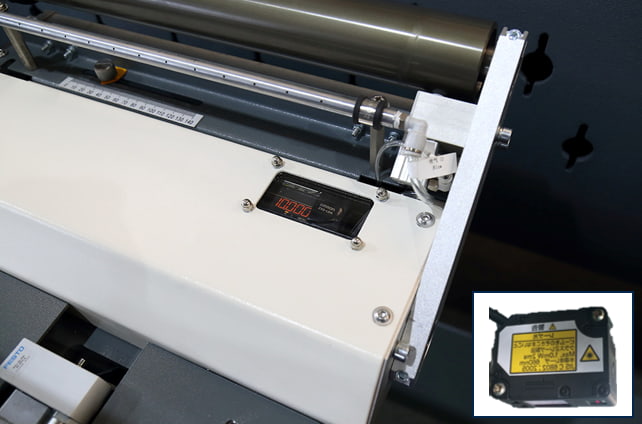

Density Monitoring System

An intelligent control system ensuring uniform section thickness.

- Automatic thickness detection for the first section.

- Automatic displacement replication for subsequent sections.

- High-precision laser sensor measurement.

- Real-time data feedback.

- Adjustable visual detection positioning.

Tension Monitoring System

An intelligent control system ensuring uniform section tension

- Automatic tension detection for strand yarn.

- Real-time tension auto-adjustment.

- Instant tension data feedback.

- Synchronized winding flatness control.

- Unaffected by spool size/warping speed.

Beaming Tension Control System

Proportional valve precision brake control.

- Auto-tensioning (inner-tight/outer-loose).

- Integrated cooling system.

- Dual-range tension switching.

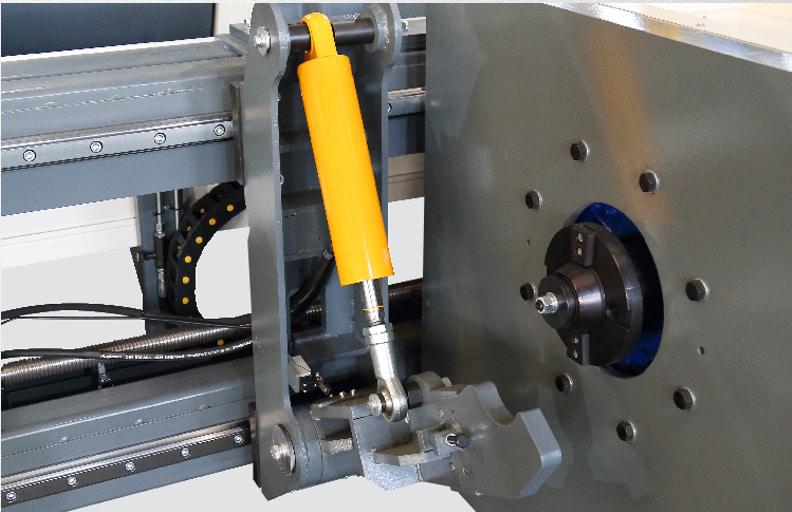

Hydraulic Load/unload Device

- Independent hydraulic unit control.

- Higher load-bearing capacity.

- Smoother vertical movement.

Clap/ Unclap

- Independent electric control.

- Left/right individually or simultaneously controllable.

- Clamping position detection.

- Clap-open ejection device.

- High-precision linear guide guidance.

1. How long is the delivery time?

The delivery time varies depending on the model and configuration. Under normal circumstances, the delivery time is 40-60 days after the date receiving down payment.

2. How long is the warranty period?

The seller provide 12 months guarantee after installation or 15 months after delivery, subject to the prior expire.

3. Can the machine be customized?

Yes. We can customize the machine according to your needs?

4. Do you provide installation service?

Yes, we do. We will send engineers to the site for installation, commissioning, and training of staff on operation.

Leave A Message

Scan to Wechat/Whatsapp :