To respond to the company's strategic requirements of lean production, continuous improvement, and enhancing front line management capabilities, as well as to inspire all employees' enthusiasm for "competing, learning, catching up, supporting, and surpassing", H-FANG held the kick-off meeting of the "Gold Standard Team Building Project" on June 30th, laying a solid foundation for the enterprise's high-quality development through management upgrading.

The project will last three months, with the first assembly workshop as the pilot team. Its core goal is to build a benchmark team with full implementation of HF988DP standard operations—accumulating replicable experience for the subsequent standardized and institutionalized management of teams across the company. Meanwhile, with skill proficiency, team positivity, job responsibility, and cross-departmental communication as core evaluation criteria, it plans to cultivate over 3 "Gold Standard Coaches". In the future, these coaches will serve as dual benchmarks for technology and professionalism, driving the improvement of all employees' skills and comprehensive quality to help the company break through bottlenecks and pursue higher goals.

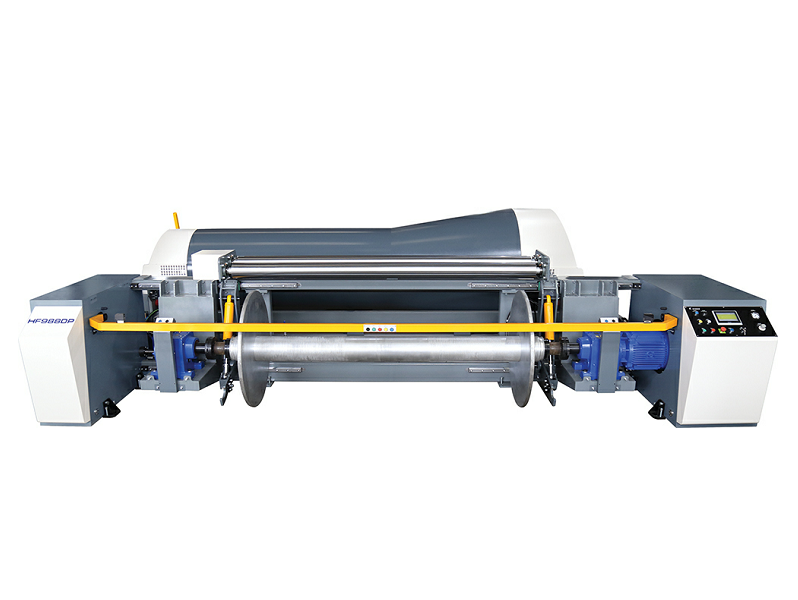

While consolidating internal management, H-FANG has also keenly grasped market changes: downstream customers’ requirements for fabric quality keep rising, and enterprise production cost pressure increases. The industry’s demand for high-efficiency textile equipment that "reduces waste in production & development and lowers dependence on employees' skills" has become more urgent. Coinciding with its 30th anniversary, the company has fully upgraded its first-generation section warping machine HF988C and launched the new 988D-PLUS—relying on 30 years of technical accumulation to help new and old customers cut costs and boost efficiency, and respond to market expectations with product innovation.

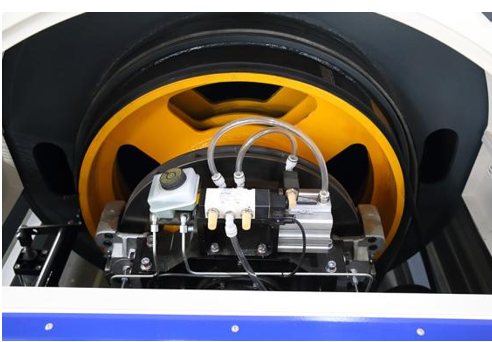

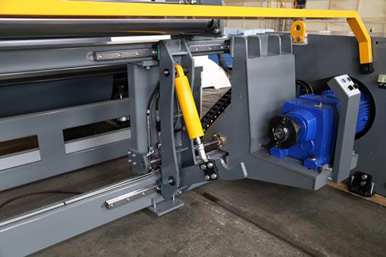

As a core upgraded product, the 988D-PLUS section warping machine focuses on "easy operation and low defect rate", especially suitable for weaving users of sizing-free yarns. Its upgrading highlights cover three core dimensions:

Beyond the above core upgrades, the 988D-PLUS also has many detailed designs meeting actual production needs. If you are interested in more technical parameters or adaptation solutions, please contact us for exclusive consultation.

Leave A Message

Scan to Wechat/Whatsapp :